Sewing contractors are businesses that provide services related to industrial sewing. Some of these services include design, prototyping, fabrication, engineering, and packaging. Contractors can provide commercial sewing services, which involve manufacturing products that are uniform and can go straight to business shelves. Additionally, contractors can provide custom-sewn fabric products for individuals which are not mass produced. Read More…

CustomFab USA has been a trusted American sewing contractor since our inception in 1990. Our 77,000 square foot high-tech manufacturing facility allows us to produce and ship a myriad of products. We have experience serving industries such as medical, sporting goods, military, aerospace, pets, and travel. With unparalleled customer service, a skilled manufacturing workforce, and tried-and-true...

LJ Design & Manufacturing is an elite sewing contractor specializing in custom sewn industrial and medical products. Since 1844, we have partnered with B2B innovators in healthcare/medicine, transportation, wearable technology, veterinary medicine, military, government, sporting goods, luggage, manufacturing and more. Highly technical products and materials are our specialties. Contact us today...

Our dedicated team of professionals is here to bring reliable and dependable products to you! At Fabri-Tech, we use our 85 years of experience to exceed your expectations. Our comprehensive process for tarps, soft luggage, pouches, and many other products are unrivaled in quality. We place emphasis on our efficient process and the highly customizable options with design. Check out our website...

Since 1979, we, at Way Out West, Inc., have been dedicated to the art and precision of contract sewing. Our team boasts extensive expertise in various sewing processes and projects, making us a reliable partner for your diverse needs. We focus on industrial sewing production at scale, servicing the military, aerospace, medical, healthcare and safety industries. We take pride in our ability to...

We sew custom-size filter bags and tubes, transfer and filtration sleeves, windsocks, cheese bandages, filter sheets, and tray liners as well as aprons and backpacks. We use FDA-approved materials for food-contact applications. Our industrial sewing machines do single- and double-needle stitches, overedge serging, and safety, chain, lock, and overlock stitching. Cotton, nylon, and poly-cotton...

At Red Fox Innovations, our philosophy is and always has been simple: we succeed when our customers succeed. With that approach, and by offering a wealth of experience and cutting-edge technology, we have become a trusted name in the cut & sew contract manufacturing industry.

CSE Packaging, we stand as a trusted leader in the realm of custom sewn products, offering a comprehensive suite of design and manufacturing solutions tailored to meet the diverse needs of our clients. With an extensive history of excellence in the industry, we have solidified our reputation for delivering unparalleled quality and craftsmanship in every project we undertake.

More Sewing Contractor Companies

Sewing contractors are specialized companies that provide a wide range of sewing and garment-related services, including garment manufacturing, custom sewing, pattern-making, cutting, and sewing assembly. These contractors work with various materials such as fabrics, textiles, leather, and synthetic materials, serving industries like fashion and apparel, home textiles, automotive, medical and healthcare, and specialized equipment and promotional merchandise. By handling tasks that other companies may lack the capacity or expertise to perform in-house, sewing contractors streamline production processes and meet diverse business demands efficiently and cost-effectively.

Sewing Contractor Products

Sewing contractors produce various items for the aircraft industry, such as ground service covers, blankets, carpets, and seating. For industries like amusement parks, retail stores, and banks, they create courier, transit, and security bags. Additionally, they manufacture a range of general fabric products, including custom bags, pouches, soft luggage, and both fitted and unfitted protective covers. Custom bags are tailored to consumer needs, using specific materials and sizes.

Pouches are a popular custom-made item suitable for carrying various products, such as manuals, infusers, flags, cameras, cables, batteries, and auto jacks. Soft luggage, made from durable materials like canvas, plastic, or leather, can be at least 21 inches or larger for airport check-ins. This category includes sports bags, briefcases, and backpacks, offering a practical alternative to bulky suitcases. These bags can be secured with clasps, buttons, or zippers.

Protective covers, made from canvas or nylon coated with paint or tar, offer effective protection against water and other outdoor elements. These covers are suitable for products like dumpsters, cars, outdoor furniture, machinery, and grills.

Unfitted covers, such as tarps, are versatile and can be used to cover swimming pools, vehicles during extreme weather, and machinery during transport. They also serve as ground or tent covers in camping applications.

History of Sewing Contractors

For thousands of years, sewing has been a fundamental activity for creating garments, bags, and bedding. Even before the invention of the needle and thread, prehistoric humans used bone and sinew to make clothing. Once the needle and thread were developed, individuals either sewed at home or hired artisans to perform the task.

Manual sewing was time-consuming and required significant skill. During the Industrial Revolution, inventors aimed to speed up and simplify the process. Thomas Saint introduced the first sewing machine in London in 1790. Later, Barthélemy Thimonnier, a French inventor, received several patents for his improved sewing machines between 1830 and 1847. Despite his efforts, his machines were not successful, and he died penniless in Amplepuis, France, in 1857.

The Singer sewing machine, patented by Isaac Singer in 1851, revolutionized the efficiency and quality of sewing. Singer’s machine could sew up to 900 stitches per minute, far surpassing the 40 stitches per minute of the best professional tailors. This invention marked a significant advancement in clothing and textile production.

Within five years, companies like Singer were mass-producing these machines for both industrial and household use. The introduction of industrial sewing machines led textile factories to replace seamstresses and tailors as the primary producers of textiles. Factories could produce numerous identical items quickly and cost-effectively, making off-the-rack clothing and bags at department stores the new standard.

Today, large-scale sewing contractors experience unprecedented demand, extending their capabilities beyond mass production. They offer custom design services for a wide range of textile-based items, including medical bags and military gear. The advancements in synthetic fabrics over the past century enable these contractors to meet specific requirements such as flame retardancy, water resistance, and enhanced durability.

Materials for Sewing Contractors

Sewing contractors employ a diverse array of fabrics to meet various industry needs. Among these materials are vinyl-coated nylon, neoprene, Hypalon, canvas, anti-static material, cotton, polyester, felt, plastic, webbing, and leather.

Vinyl-coated nylon is renowned for its durability, weather resistance, and lightweight properties. These characteristics make it an ideal choice for crafting protective covers, presentation cases, and bags.

Neoprene stands out for its chemical resistance, abrasion resistance, and insulative qualities. Commonly used in the production of fly fishing waders, wetsuits, and leggings, neoprene is a cost-effective material. However, it does have limitations, notably its lack of breathability.

Hypalon, akin to neoprene, demonstrates exceptional resistance to abrasion, cutting, and chemicals, making it a preferred choice in various industrial applications. Notably, Hypalon surpasses neoprene in strength and weight, offering enhanced performance and efficiency.

Canvas, a breathable material composed of felt, flannel, and twill, finds utility in both industrial applications and the creation of bags and curtains. Its popularity for custom bags stems from its unique combination of softness and resilience, providing both comfort and durability.

Anti-static materials, such as ESD fabric, are integral to the electronics and computer industries. These materials are crucial as they effectively manage and dissipate static buildup and electromagnetic discharge, mitigating potential disruptions to electronic functionality.

Cotton is a soft material sourced from the cotton plant. It can be dry cleaned, machine washed, and printed on. It retains color well, has good absorbency, strength, and drapability.

Polyester fabrics are synthetic and designed to be incredibly strong, chemical-resistant, mildew-resistant, abrasion-resistant, wrinkle-resistant, and resistant to stretching and shrinking. They dry quickly and can be made insulative.

Felt fabric is made from compressed and matted fibers, typically wool mixed with synthetic fiber or entirely synthetic. Dense and non-woven, felt is durable and sturdy, suitable for both industrial and craft applications.

Plastic encompasses a wide range of versatile synthetic and semi-synthetic polymer materials. Although plastics are not commonly associated with sewing, many can be adapted for a variety of contract sewing applications. For instance, nylon is used in manufacturing parachutes, tents, flags, and clothing items such as hosiery.

Webbing, a woven fabric typically made from polyester, polypropylene, or nylon, is another essential material. For enhanced strength, contractors may use materials like Kevlar. There are two primary forms of webbing: tubular and flat. Tubular webbing is woven into a flat tube, making it suitable for industrial and climbing applications. In contrast, flat webbing is woven into a solid flat weave, commonly used for backpack straps and seat belts.

Leather, derived from tanned rawhides, particularly cattle hides, is renowned for its strength, durability, and resistance to tears and punctures. It also provides excellent insulation, making it ideal for cold weather. Contract sewers utilize leather to create a wide array of products, including jackets, shoes, and bookbindings.

Working with Sewing Contractors

After consulting with a customer, sewing contractors begin with the planning phase. A pattern designer creates the blueprint for the requested product, often using computer software. This blueprint includes scaled dimensions and distinguishable sections. Once the plans are clearly recorded, textile experts select the fabrics and produce a small sample. This sample is then shared with the client for approval. Upon receiving approval, full-scale production commences, involving processes such as cutting, stitching, weaving, embroidering, and printing.

Sewing contractors design their products based on your specific application. They provide custom fitting, free prototypes, custom embroidery, and the production of clothing labels for commercial items. Custom embroidery can include descriptive images or text, and logos can be added to uniforms and products upon request. For all commercially sold bedding, textiles, clothing, and garments, contractors attach tags with details on materials, origin, size, and care instructions. These tags may be crafted from satin, taffeta, or damask and can be affixed through printing, weaving, or embroidery.

Sewing Contractor Machinery

Sewing contractors utilize a range of equipment to ensure the success of their projects, from basic tools like single-needle sewing machines and cutting scissors to advanced automated machines.

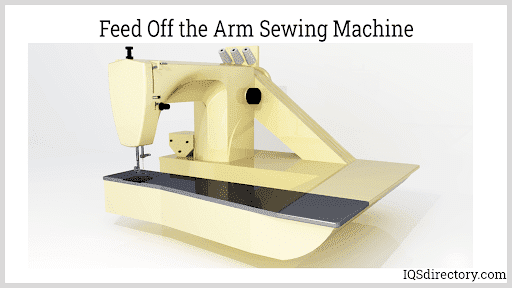

Key textile manufacturing machines include straight stitch, serger, and blind stitch models. Specialized machines encompass lockstitch, chain stitch, overedge, walking foot, needle feed, double needle, zigzag, cylinder, bar tack, box tack, and hook/loop fastener types.

Industrial sewing machines differ from consumer models in several ways: they operate faster, handle multiple layers and heavy-duty fabrics, and are equipped with larger motors to run continuously. These machines are self-oiling and require minimal manual operation. However, their complex configuration necessitates regular maintenance by a mechanic.

Benefits of Sewing Contractors

Sewing contractors provide significant benefits to businesses. By outsourcing sewing tasks to these specialists, companies can direct their focus towards core activities and strategic priorities. This shift in responsibility allows businesses to invest their resources in product design, marketing, and business development, leading to increased efficiency and productivity.

The expertise of sewing contractors enhances garment production. Their skilled staff, experienced in working with diverse materials and advanced machinery, ensures high-quality craftsmanship that meets the rigorous standards expected by customers and clients.

Working with sewing contractors can be a cost-effective strategy for businesses. Establishing and managing an in-house sewing department involves substantial investments in equipment, facilities, and personnel training. Outsourcing to sewing contractors eliminates these capital expenditures and ongoing overhead costs, leading to potential savings.

Additionally, sewing contractors provide enhanced flexibility in production capacity. They can swiftly adjust operations to meet fluctuating demand, helping businesses manage inventory and meet tight deadlines more effectively. This adaptability is particularly advantageous for seasonal businesses or those with variable order volumes.

Partnering with sewing contractors opens up a wealth of sewing services and expertise. These contractors are equipped to handle a spectrum of projects, ranging from intricate custom orders to extensive manufacturing runs. Their versatility allows businesses to precisely meet client needs and address diverse market segments.

In essence, working with sewing contractors brings significant advantages, including specialized knowledge, cost-effectiveness, and adaptability. By harnessing their capabilities, companies can refine their operations, elevate product quality, and respond more adeptly to market demands, thereby driving industry success and growth.

Sewing Contractor Services

To find the ideal sewing contractor services, companies should start by analyzing their production requirements. This involves examining the types of products they produce and pinpointing the sewing-related tasks necessary for their manufacturing process. For instance, garment production might be needed by a fashion company, whereas upholstery and interior component sewing might be required by an automotive firm. Clarifying these needs will help in selecting the right services from a contractor.

In addition, evaluating production volume and capacity is crucial. Companies that experience fluctuating or inconsistent order volumes may benefit from a contractor who offers flexible production capabilities. Conversely, businesses with steady, high-volume production should look for a contractor capable of efficiently managing large-scale manufacturing.

It’s crucial to evaluate in-house capabilities. For a company with existing sewing skills but missing specialized expertise or machinery, a contractor who can provide these elements is ideal. For example, a firm skilled in pattern-making but lacking large-scale production capacity would benefit from partnering with a contractor who has the necessary production facilities.

Additionally, considering growth plans and long-term objectives is important. A contractor who can adapt to evolving needs and support potential product diversification will be a strategic asset.

By thoroughly reviewing their sewing needs, production volume, internal strengths, and future goals, companies can pinpoint the contractor services that will be most advantageous. This assessment will help in choosing a partner who effectively meets their needs and enhances overall business success.

Things to Consider

If you’re considering ordering textiles, review the companies listed on this page, as they are established experts and innovators. First, compile a list of your specifications, including the textile’s application, environmental conditions, dimensions, custom stitching, color preferences, request volume, deadlines, delivery preferences, budget, and standard requirements. With your list prepared, browse the recommended companies, select three or four that best meet your needs, and discuss your project with them. Compare their responses, focusing on customer service, to choose the most suitable option.

Check out our Carrying Cases website

Check out our Industrial Ovens website

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services