Commercial sewing is a vital aspect of many businesses that require sewing services. From the fashion industry to medical device manufacturing, commercial sewing is essential in creating high-quality and durable products. In this article, we’ll explore the different types of commercial sewing services available, common materials and techniques used in commercial sewing, considerations regarding commercial sewing businesses, the benefits of using commercial sewing services for businesses, and various applications of commercial sewing. Read More…

CustomFab USA has been a trusted American sewing contractor since our inception in 1990. Our 77,000 square foot high-tech manufacturing facility allows us to produce and ship a myriad of products. We have experience serving industries such as medical, sporting goods, military, aerospace, pets, and travel. With unparalleled customer service, a skilled manufacturing workforce, and tried-and-true...

LJ Design & Manufacturing is an elite sewing contractor specializing in custom sewn industrial and medical products. Since 1844, we have partnered with B2B innovators in healthcare/medicine, transportation, wearable technology, veterinary medicine, military, government, sporting goods, luggage, manufacturing and more. Highly technical products and materials are our specialties. Contact us today...

Our dedicated team of professionals is here to bring reliable and dependable products to you! At Fabri-Tech, we use our 85 years of experience to exceed your expectations. Our comprehensive process for tarps, soft luggage, pouches, and many other products are unrivaled in quality. We place emphasis on our efficient process and the highly customizable options with design. Check out our website...

Since 1979, we, at Way Out West, Inc., have been dedicated to the art and precision of contract sewing. Our team boasts extensive expertise in various sewing processes and projects, making us a reliable partner for your diverse needs. We focus on industrial sewing production at scale, servicing the military, aerospace, medical, healthcare and safety industries. We take pride in our ability to...

We sew custom-size filter bags and tubes, transfer and filtration sleeves, windsocks, cheese bandages, filter sheets, and tray liners as well as aprons and backpacks. We use FDA-approved materials for food-contact applications. Our industrial sewing machines do single- and double-needle stitches, overedge serging, and safety, chain, lock, and overlock stitching. Cotton, nylon, and poly-cotton...

At Red Fox Innovations, our philosophy is and always has been simple: we succeed when our customers succeed. With that approach, and by offering a wealth of experience and cutting-edge technology, we have become a trusted name in the cut & sew contract manufacturing industry.

CSE Packaging, we stand as a trusted leader in the realm of custom sewn products, offering a comprehensive suite of design and manufacturing solutions tailored to meet the diverse needs of our clients. With an extensive history of excellence in the industry, we have solidified our reputation for delivering unparalleled quality and craftsmanship in every project we undertake.

More Commercial Sewing Companies

Types of Commercial Sewing Services

There are three main types of commercial sewing services: contract sewing, cut and sew, and private label production. Contract sewing is a service where a business hires a sewing company to complete a specific sewing project. Cut and sew involves cutting fabrics and sewing them together to create a finished product. Private label production is where a business hires a sewing company to manufacture products under their brand name. Each of these services has its unique benefits depending on the business's needs.

Materials and Techniques Used in Commercial Sewing

Various materials and techniques are used in commercial sewing. The most common materials used in commercial sewing are cotton, polyester, and nylon. Cotton is preferred for its softness, breathability, and durability, making it ideal for clothing and home goods. Polyester is durable and resistant to wrinkles, making it ideal for workwear and uniforms. Nylon is water-resistant and durable, making it ideal for outdoor gear, such as backpacks and tents.

Meanwhile, common techniques used in commercial sewing include serging, flat-felled seams, and box pleats. Serging is a technique that uses an overlocking stitch to prevent fabrics from fraying. Flat-felled seams are used to create a clean and durable finish on clothing, while box pleats are used to add fullness to a garment. Each technique is preferred for specific applications and helps create high-quality and durable products.

Considerations Regarding Commercial Sewing Businesses

There are several considerations to take into account regarding commercial sewing businesses, including sourcing materials, managing production schedules, ensuring quality control, hiring and retaining skilled labor, and mitigating costs. Sourcing materials can be a challenge due to limited availability and fluctuating costs. Managing production schedules requires careful planning to meet deadlines while ensuring quality control. Additionally, ensuring quality control is always more difficult when production is performed off-site. Hiring and retaining skilled labor can be difficult,as well, as skilled workers are in high demand. Mitigating costs requires efficient production processes and careful cost management.

Benefits of Using Commercial Sewing Services

Despite such considerations, using commercial sewing services offers many benefits for businesses. Commercial sewing companies have specialized equipment and expertise, enabling them to produce high-quality products quickly and efficiently. Outsourcing sewing services allows businesses to focus on other aspects of their business while saving costs. Additionally, access to specialized equipment and expertise allows businesses to create products that meet their customers' unique needs while scaling production quickly.

Applications of Commercial Sewing

Commercial sewing is used in various industries, including apparel manufacturing, home goods manufacturing, automotive manufacturing, medical device manufacturing, and other industrial and commercial applications. These applications are explained in more detail below.

Apparel Manufacturing

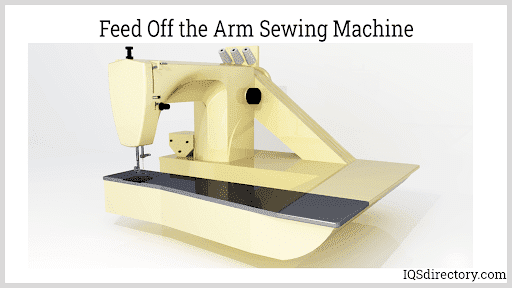

Commercial sewing is extensively used in apparel manufacturing. Clothing manufacturers use commercial sewing machines to create a wide range of garments, from t-shirts to formal wear. Different types of commercial sewing machines are used depending on the fabric and the type of stitch required. For example, overlock machines are used to create neat and durable seams on knit fabrics, while lockstitch machines are used to create more precise and decorative stitches on woven fabrics. Sewing companies also use specialized machines for specific tasks such as buttonholing, hemming, and embroidery.

Home Goods Manufacturing

Commercial sewing is also used in home goods manufacturing. Sewing companies create products such as curtains, bedspreads, pillowcases, and upholstery for furniture. Like apparel manufacturing, different types of commercial sewing machines are used depending on the fabric and the type of stitch required. For example, heavy-duty machines are used for upholstery fabrics, while lighter machines are used for creating delicate lace or embroidery.

Automotive Manufacturing

Commercial sewing is widely used in automotive manufacturing for creating upholstery and car covers. The upholstery in cars not only provides comfort but also helps to protect the interior of the car from wear and tear. The stitching used in automotive upholstery is different from that used in apparel or home goods manufacturing. The sewing companies that specialize in automotive upholstery use specialized machines that can handle heavy-duty materials such as leather or vinyl.

Medical Device Manufacturing

Commercial sewing is also used in medical device manufacturing. Medical devices require precision and accuracy in their construction. Sewing companies use specialized machines and materials to create durable and reliable products such as medical bags, surgical gowns, and patient slings. These products need to meet strict regulatory requirements, and sewing companies must maintain strict quality control measures to ensure compliance.

Other Industrial and Commercial Applications

Commercial sewing is used in other industrial and commercial applications, such as creating tents, bags, tarps, and outdoor gear. Sewing companies use specialized materials such as nylon, polyester, and PVC to create products that are durable and water-resistant. These products need to be able to withstand harsh environments and weather conditions, and commercial sewing plays a vital role in ensuring their durability.

Choosing the Right Commercial Sewing Company

To ensure you have the most beneficial outcome when choosing a commercial sewing company, it is important to compare several businesses using our directory of commercial sewing companies. Each commercial sewing company has a business profile page highlighting their areas of experience and capabilities, along with a contact form to directly communicate with the company for more information or to request a quote. Review each commercial sewing business website using our patented website previewer to quickly learn what each company specializes in. Then, use our simple RFQ form to contact multiple commercial sewing companies with the same form.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services