The prototype and design stage of contract sewing is used to identify design faults and create solutions. Fundamentally, prototype and design is based on the notion that while ideas and creations may appear stunning when produced by a computer, they may not be useful during production. Therefore, catching flaws and errors before they are put into production saves time and money. Read More…

CustomFab USA has been a trusted American sewing contractor since our inception in 1990. Our 77,000 square foot high-tech manufacturing facility allows us to produce and ship a myriad of products. We have experience serving industries such as medical, sporting goods, military, aerospace, pets, and travel. With unparalleled customer service, a skilled manufacturing workforce, and tried-and-true...

LJ Design & Manufacturing is an elite sewing contractor specializing in custom sewn industrial and medical products. Since 1844, we have partnered with B2B innovators in healthcare/medicine, transportation, wearable technology, veterinary medicine, military, government, sporting goods, luggage, manufacturing and more. Highly technical products and materials are our specialties. Contact us today...

Our dedicated team of professionals is here to bring reliable and dependable products to you! At Fabri-Tech, we use our 85 years of experience to exceed your expectations. Our comprehensive process for tarps, soft luggage, pouches, and many other products are unrivaled in quality. We place emphasis on our efficient process and the highly customizable options with design. Check out our website...

Since 1979, we, at Way Out West, Inc., have been dedicated to the art and precision of contract sewing. Our team boasts extensive expertise in various sewing processes and projects, making us a reliable partner for your diverse needs. We focus on industrial sewing production at scale, servicing the military, aerospace, medical, healthcare and safety industries. We take pride in our ability to...

We sew custom-size filter bags and tubes, transfer and filtration sleeves, windsocks, cheese bandages, filter sheets, and tray liners as well as aprons and backpacks. We use FDA-approved materials for food-contact applications. Our industrial sewing machines do single- and double-needle stitches, overedge serging, and safety, chain, lock, and overlock stitching. Cotton, nylon, and poly-cotton...

At Red Fox Innovations, our philosophy is and always has been simple: we succeed when our customers succeed. With that approach, and by offering a wealth of experience and cutting-edge technology, we have become a trusted name in the cut & sew contract manufacturing industry.

CSE Packaging, we stand as a trusted leader in the realm of custom sewn products, offering a comprehensive suite of design and manufacturing solutions tailored to meet the diverse needs of our clients. With an extensive history of excellence in the industry, we have solidified our reputation for delivering unparalleled quality and craftsmanship in every project we undertake.

More Contract Sewing Companies

Contract sewers hire their sewing expertise to manufacturers or contract sewing businesses to finish minor projects with a minimum of 100 pieces. They produce garments and other complicated products and are extremely proficient in various stitching techniques.

The wide variety of materials and fabrics utilized to make their products, including vinyl-coated nylon, neoprene, canvas, cotton, anti-static materials, felt, polyester, webbing, plastic, and leather, is a significant advantage of contract sewing. The designs and creations that clients submit become the basis for the products that the sector produces.

Contract Sewing Process

The process of contract sewing is a commercial technique for mass-producing a variety of goods for industrial and commercial usage. Therefore, choosing parts that will be sewn securely together during the production of these products is necessary.

Prototype and Design

The prototype and design stage of contract sewing is used to identify design faults and create solutions. Fundamentally, prototype and design is based on the notion that while ideas and creations may appear stunning when produced by a computer, they may not be useful during production. Therefore, catching flaws and errors before they are put into production saves time and money.

Sewing Pattern

With a 3D sample from CAD, there is no longer a need to make a physical sample for fashion shoots or customer communications; these tasks can now be carried out online. Using CAD, it is now possible to keep patterns online for upcoming projects rather than in a backroom. A pattern designer or technical designer in charge of manufacturing can quickly receive the finished CAD rendering. Since there is only one way to complete the procedure, each product's instructions are unique to the design. The guidelines for contract sewing are brief. In most circumstances, the contractor is left to make decisions without guidance.

The electronic pattern process covers every step of product development. It shows the cuts for all of the various sizes for garments as well as the cutting techniques. Determining the usage of the materials used in the production process, which affects the ultimate cost, is a crucial step in this process.

Selection of Material

Once the manufacturing plan has been approved, the pattern is graded and marked to calculate the yield. This helps estimate how much fabric is required for zippers, buttons, lining, and other embellishments. Upon receiving the fabric, a pre-production sample is created.

Pattern Cutting

The pattern is laid on the fabric to be cut during the cutting process. The pattern's instructions are followed when cutting through several layers of cloth using an extremely sharp saw-like cutting instrument. Although this procedure is used to create cloth or apparel, it may differ when heavier materials like leather or vinyl are included. An automated high-ply cutting machine made specifically for cutting clothing is a more effective form of cutting than the hand method. The cutting instructions are carried out on a computer that has devised the best method for cutting fabric in a way that produces the least amount of waste.

Sewing

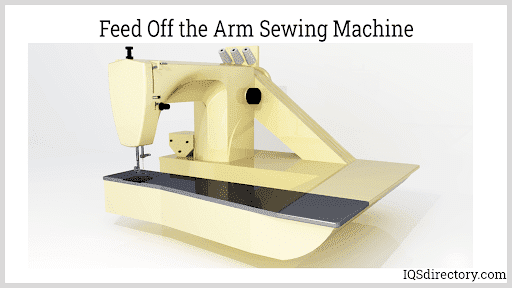

Contrary to a single person sitting at a sewing machine, the sewing method used in contract or industrial sewing is very different. The process of assembling something is comparable to that of an assembly line. Every participant completes one component of the final product, which is processed through several steps before being finalized. A person's single task can be attaching a piece, including a stitch or clip, or shifting the material's location.

Uses for Contract Sewing

Businesses specializing in something other than sewing or needlework need the support of the contract sewing sector. The requirement for manufacturers to have clothing stitched for products they had created but could not make gave rise to the industry.

Airbags in Contract Sewing

Airbags are difficult to sew because they must be both big enough to protect the car's occupants and sufficiently small to fit in a compact space. To endure the force of deployment, the fabric used to make airbags is extremely compact and dense. Before being put inside an automobile, the thickly covered material is cut, sewed, and tested.

Knee Pads in Contract Sewing

For added safety, knee pads are manufactured with reinforced stitching. Nylon, neoprene, and PVC are used in their construction to increase strength and longevity. Knee pads of the industrial type are designed to shield employees from objects like nails, shards of glass, and other debris. They need to be comfortable but also provide extra support for the tendons and muscles in the legs.

Other uses of contract sewing includes:

- Industrial aprons

- Luggage bag

- Airplane seatbelts

- Uniforms

- Chairs

- Space suits

- Industrial curtains

Choosing the Right Contract Sewing Company

To make sure you have the most positive outcome when selecting a contract sewer, it is important to compare at least 4 companies using our contract sewing directory. Each contract sewing company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the company for more information or request a quote. Review each contract sewing business website using our proprietary website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple companies with the same quote.

Cardboard Tubes

Cardboard Tubes Carrying Cases

Carrying Cases Contract Packaging

Contract Packaging Corrugated Boxes

Corrugated Boxes Dot Peening Machines

Dot Peening Machines Labeling Machinery

Labeling Machinery Marking Machinery

Marking Machinery Packaging Equipment

Packaging Equipment Palletizers

Palletizers Plastic Bags

Plastic Bags Sewing Contractors

Sewing Contractors Tape Suppliers

Tape Suppliers Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services